Inflatable Bag Neck Seals and Seamless Rubber Tubing

Introduction

Ensure efficiency, accuracy, and reliability in industrial bag filling. At Flexible Connections Ltd., we pride ourselves on delivering solutions that enhance these critical aspects of industrial operations. Our key offerings are Inflatable Bag Neck Seals, Bulk Bag Seals, and Seamless Rubber Tubing.

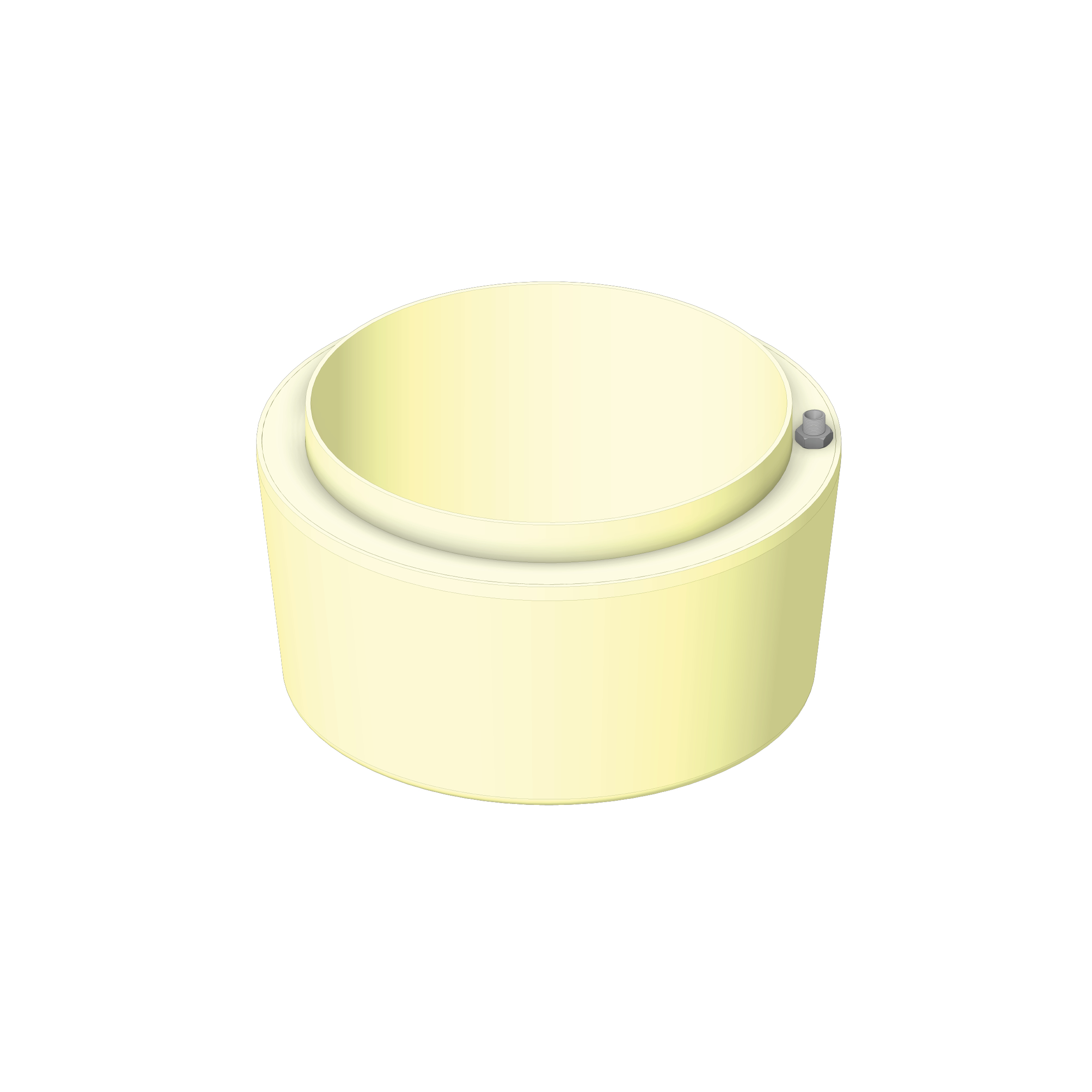

Inflatable Bag Neck Seals: Enhancing Industrial Bag-Filling Efficiency

Overview

Inflatable Bag Neck Seals, or Bulk Bag Seals, are versatile and efficient solutions designed to optimise the bagging process in industrial settings. These specialised seals enhance bag-filling operations’ efficiency, accuracy, and performance.

Key Features

- Adjustable Inflation

- Precision Control: Our Inflatable Bag Seals are equipped with a 1/4″ BSP Female socket, allowing you to connect your airline for precise control over the level of inflation. This adaptability ensures a secure and tailored seal for various bag sizes and materials.

- Flexibility: The elongation of these rubber seals allows them to adapt to different bagging requirements, ensuring a perfect fit regardless of the bag’s dimensions or material.

- Versatility

- Material Compatibility: Our Inflatable Bag Seals accommodate a wide range of bulk bag materials, including paper, plastic, and woven materials. This versatility makes them suitable for diverse industrial bag-filling applications.

- Universal Fit: They can effectively seal bags of different sizes, shapes, and materials, offering a universal solution for various industrial needs.

- Quick and Efficient Sealing

- Streamlined Process: These inflatable seals streamline the bagging process, providing quick and efficient sealing. Their inflatable nature allows for rapid adjustment and adaptation to changing production requirements, significantly reducing downtime.

- Enhanced Productivity: These seals’ speed and ease of use contribute to increased productivity in the bagging operation.

- Consistent Seal Quality

- Reliability: Inflatable Bag Seals ensure consistent seal quality, minimising the risk of leaks, spills, or contamination during the bag-filling process. This consistency contributes to the overall reliability of the packaging operation.

- Quality Assurance: The uniformity in sealing helps maintain high standards of quality control in industrial applications.

- Adaptable to Automated Systems

- Automation Compatibility: Our Inflatable Bag Seals are often compatible with automated bag-filling systems. Their adaptability to automation enhances the speed and accuracy of the packaging process, reducing manual intervention and increasing overall productivity.

- Technological Integration: Integration with automated systems ensures seamless operation, optimising the efficiency of the entire bag-filling process.

- Durable Construction

- Robust Materials: Constructed from durable materials, our Inflatable Bag Seals withstand the rigours of industrial bag-filling environments. The strong construction ensures longevity and reliability, even in demanding production settings.

- Long-Lasting Performance: The durability of these seals translates to reduced maintenance costs and longer service life.

- Easy Maintenance

- User-Friendly Design: Our inflatable bag seal’s design makes inspection and replacement quick and easy, contributing to the overall efficiency of the bagging operation.

- Minimised Downtime: Easy maintenance procedures help minimise downtime, ensuring continuous operation.

- Customisation Options

- Tailored Solutions: We can accommodate custom sizes, shapes, and materials based on the unique needs of the industrial bag-filling process. This customisation ensures that each seal is ideally suited to its specific application.

- Customer Satisfaction: Providing tailored solutions helps meet the exact requirements of our clients, enhancing their satisfaction and the performance of their operations.

Manufacturing Process at Flexible Connections Ltd.

At Flexible Connections Ltd., we employ a meticulous manufacturing process to ensure the highest quality of Inflatable Bag Seals:

- Material Selection: We use high-grade materials that offer durability and reliability.

- Design and Engineering: Our team designs the seals to meet specific customer requirements, ensuring precision and functionality.

- Production: Utilising advanced machinery and techniques, we manufacture the seals strictly adhering to quality control standards.

- Quality Assurance: Before being delivered to the customer, each seal undergoes rigorous testing to ensure it meets our stringent quality criteria.

Applications of Inflatable Seals

- Industrial Machinery: Providing secure seals in machinery to prevent leaks and contamination.

- Pharmaceuticals: Ensuring hygienic sealing solutions in production environments.

- Food and Beverage: Maintaining cleanliness and efficiency in processing and packaging operations.

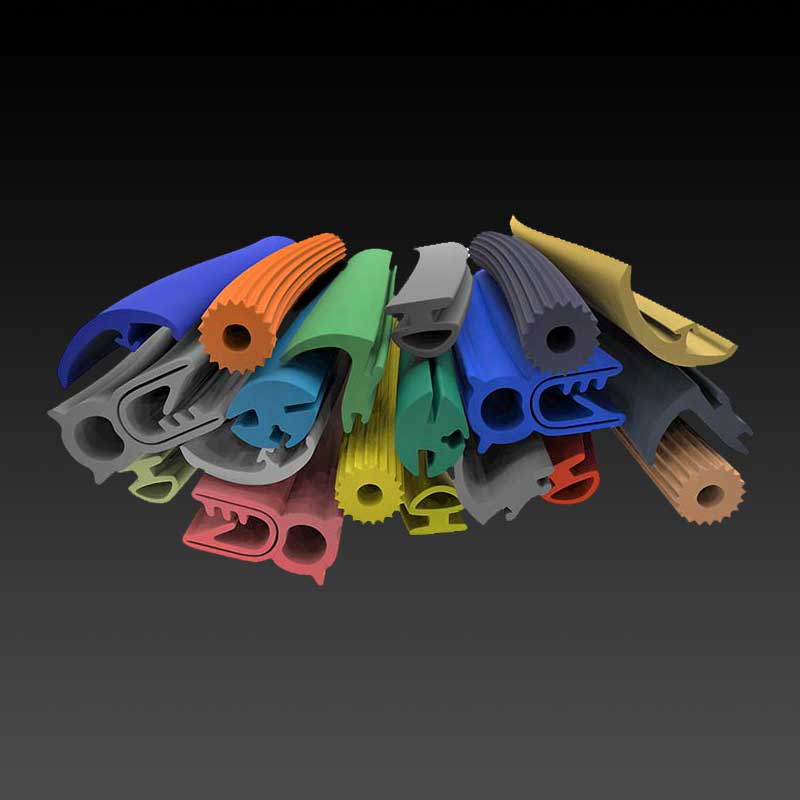

Seamless Rubber Tubing: Advantages and Applications

Overview

Seamless rubber tubing offers excellent benefits for conveying product material in various industrial applications. Unlike standard sleeves with bonded joints, seamless rubber tubing eliminates weak points, enhancing durability and performance.

Key Features

- No Bonded Joints

- Integrity: Seamless construction means no weak points, ensuring the tubing maintains its integrity under pressure.

- Enhanced Strength: The absence of joints reduces the risk of failure, making the tubing more robust and reliable.

- Flexibility

- Versatile Applications: Seamless rubber tubing is highly flexible, making it suitable for various applications.

- Adaptability: Its flexibility allows it in situations where standard tubing may not be suitable.

- Reinforcement Options

- Pressure Rating: We can incorporate reinforcement layers into the rubber wall, giving the connector a pressure rating suitable for heavier-duty applications.

- Customisation: Reinforcement options can meet specific requirements, ensuring the tubing performs optimally under various conditions.

- Material Benefits

- Chemical Resistance: Our seamless rubber tubing is manufactured from different rubber compounds. These can withstand various chemicals, ensuring longevity and reliability in harsh environments.

- Temperature Tolerance: The materials used can withstand extreme temperatures, making the tubing suitable for various industrial applications.

Manufacturing Process at Flexible Connections Ltd.

- Material Selection: High-quality rubber materials are selected based on the application requirements.

- Reinforcement: If required, reinforcement layers are added during extrusion to enhance the tubing’s pressure rating and durability.

- Quality Control: Each tube undergoes thorough testing to meet the required specifications and performance standards.

- Customisation: Tubes can be customised in size, length, and reinforcement to meet each client’s unique needs.

Applications of Seamless Rubber Tubing

- Pharmaceuticals: For transporting sensitive materials without contamination.

- Food and Beverage: Ensuring hygienic conveyance of liquids and semi-liquids.

- Industrial: For general fluid transfer and pneumatic applications.

Conclusion

Inflatable Bag Neck Seals, Seamless Rubber Tubing, and Inflatable Bladder Seals from Flexible Connections Ltd. Enhance industrial operations’ efficiency, reliability, and performance. Our commitment to quality, precision, and customer satisfaction ensures that we deliver top-notch products tailored to each application’s unique needs.

By leveraging advanced manufacturing processes, high-quality materials, and customisation options, we provide solutions that optimise the performance of industrial systems across various sectors. Explore our comprehensive range of products today and discover how Flexible Connections Ltd. can enhance your operations with our innovative sealing solutions. Contact us to discuss your requirements, and we will provide you with the perfect solution tailored to your needs.