The Benefits and Purpose of Rubber Expansion Bellows

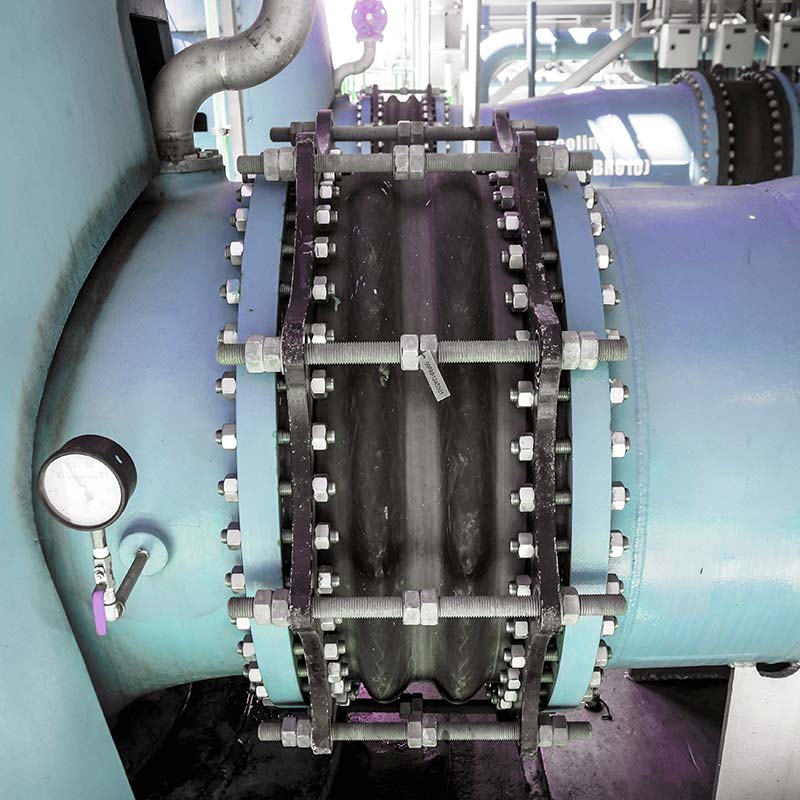

Rubber expansion bellows, also known as moulded rubber expansion joints or flexible connectors, are integral components in piping systems designed to absorb movement, vibrations, and misalignments between connected sections. They are manufactured from various rubber materials, including natural rubber, neoprene, and nitrile rubber, and offer unparalleled flexibility and resilience. Our rubber expansion bellows are UK stocked, making them readily available to same-day dispatch, ruducing downtime on site.

Purpose of Rubber Expansion Bellows

The primary function of rubber expansion bellows is to absorb vibrations and shocks within a piping system. This capability is crucial in preventing stress, fatigue, and damage to the piping and associated equipment due to movements caused by temperature variations, pressure fluctuations, or dynamic forces. By accommodating these movements, rubber expansion bellows maintain the integrity and longevity of the entire piping system.

- Absorbing Vibrations and Shocks:

- Dynamic Forces: Industrial environments are rife with dynamic forces that can cause vibrations and shocks within piping systems. Rubber bellows effectively dampen these forces, preventing potential damage.

- Pressure Fluctuations: Changes in pressure within a system can cause pipes to expand and contract. Rubber bellows accommodate these variations, preventing undue stress on the pipes.

- Managing Thermal Expansion:

- Temperature Variations: Thermal expansion due to temperature changes can cause pipes to expand and contract. Rubber bellows absorb these expansions and contractions, maintaining the system’s stability.

- Extreme Temperatures: In high-heat environments or extreme cold, rubber bellows provide the flexibility to handle temperature-induced movements.

- Accommodating Misalignment:

- Installation Tolerances: During the installation of piping systems, perfect alignment is often challenging to achieve. Rubber bellows accommodate minor misalignments, ensuring a secure fit.

- System Adjustments: Piping systems might shift over time due to settling or external forces. Rubber bellows adjust to these changes, maintaining the system’s integrity.

Construction and Materials

Rubber expansion bellows are constructed to provide maximum durability and flexibility. The choice of materials plays a critical role in their performance.

- Materials:

- Natural Rubber: Offers excellent flexibility and resilience, suitable for various general-purpose applications.

- Neoprene: Known for its good chemical stability and flexibility over a wide temperature range.

- Nitrile Rubber: Resistant to oils and fuels, making it ideal for applications involving these substances.

- EPDM: Excellent resistance to heat, weather, and ozone, making it suitable for outdoor applications.

- Viton and Hypalon: High resistance to chemicals, heat, and corrosion, used in more demanding environments.

- Design Features:

- Convolutions: The bellows are designed with multiple convolutions, allowing them to expand, contract, and absorb movements effectively.

- Reinforcements: Some designs include wire or fabric reinforcements to enhance strength and durability.

Design Considerations

Rubber expansion bellows come in various designs to accommodate specific movement requirements in different directions. The main types include:

- Axial Bellows:

- Expansion and Contraction: Designed to handle movements along the axis of the pipe.

- Thermal Expansion: Commonly used to absorb thermal expansion and contraction.

- Lateral Bellows:

- Side-to-Side Movement: Allow for lateral movement between two connected sections.

- Misalignment Compensation: Useful for compensating for misalignments during installation or due to shifts over time.

- Angular Bellows:

- Rotational Movement: Designed to accommodate angular movement or rotation.

- Flexibility: Ideal for applications requiring a high degree of flexibility.

Applications

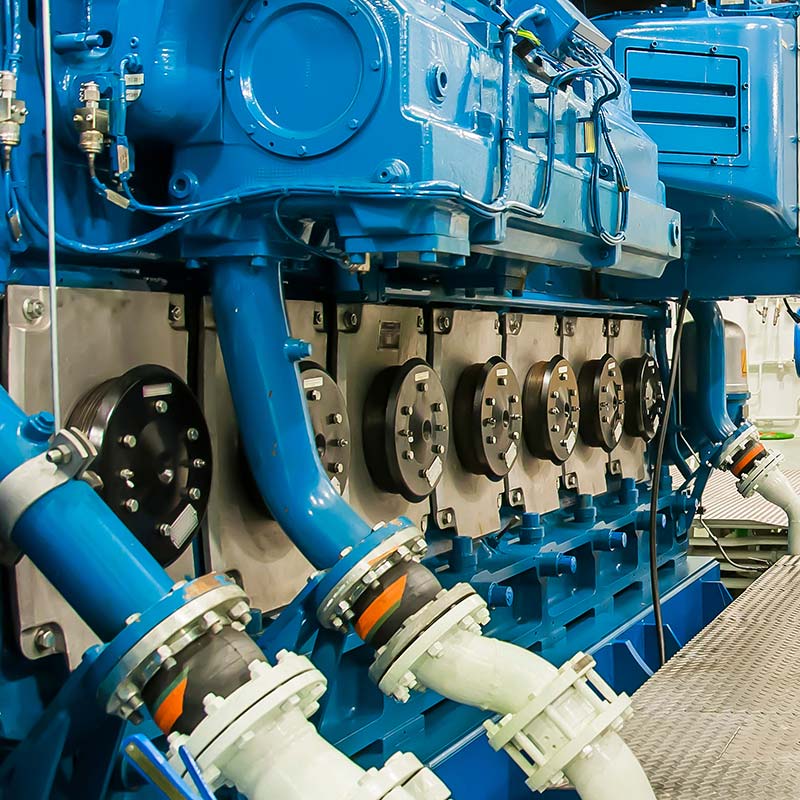

Rubber expansion bellows are used across various industries for their versatility and reliability.

- HVAC Systems:

- Air Handling Units: Absorb vibrations and reduce noise in HVAC systems.

- Ductwork: Accommodate thermal expansion and misalignments in duct systems.

- Power Plants:

- Steam and Water Pipes: Handle steam or water pipes’ thermal expansion and contraction.

- Vibration Dampening: Reduce vibrations from machinery and equipment.

- Chemical Plants:

- Chemical Resistance: Suitable for piping systems carrying chemicals, thanks to the chemical resistance of materials like Viton and Hypalon.

- Dynamic Movements: Absorb dynamic movements caused by pressure changes and fluid dynamics.

- Pipelines:

- Oil and Gas: Used in pipelines transporting oil and gas, where flexibility and durability are critical.

- Fluid Transport: Ensure fluids’ safe and efficient transport under varying pressures and temperatures.

Benefits

The benefits of using rubber expansion bellows in piping systems are extensive, contributing to the overall performance and longevity of the systems.

- Flexibility:

- Movement Absorption: Can absorb axial, lateral, and angular movements.

- Vibration Dampening: Reduce the impact of vibrations, protecting sensitive components.

- Durability:

- Resilient Materials: Constructed from high-quality materials that offer long-lasting performance.

- Weather and Chemical Resistance: Materials like EPDM, Viton, and Hypalon resist environmental factors and chemicals.

- Customization:

- Variety of Sizes: Available in various sizes to suit applications, from 25mm to 600mm in diameter.

- End Fittings: To match specific requirements, Customise end fittings, including flanges and union end fittings.

- Ease of Installation:

- Misalignment Accommodation: Simplify installation by accommodating misalignments and reducing the need for precise alignment.

- Installation Tolerances: Provide flexibility in installation tolerances, making them easier to fit into existing systems.

- Cost-Effectiveness:

- Reduced Maintenance: By absorbing movements and vibrations, rubber bellows reduce wear and tear on piping systems, lowering maintenance costs.

- Long Service Life: Durable materials and construction extend the service life of the bellows, providing long-term cost savings.

- UK Stocked: Most rubber expansion bellows are readily available from stock for same day dispatch.

UK-Stocked for Fast Dispatch

Flexible Connections offers a range of UK-stocked rubber expansion bellows, ensuring quick availability and dispatch to minimise downtime. The bellows come with mild or stainless steel spinning flanges and can be customised to match any flange table or non-standard drilling. We also provide bellows with mild steel female union end fittings, suitable for various bore sizes.

Custom Solutions

Hand-fabricated rubber bellows offer a tailored solution for applications where standard sizes are unsuitable. These custom bellows are designed to meet specific on-site requirements, ensuring optimal performance in unique applications.

Click here for more information.

Conclusion

Rubber expansion bellows are essential in modern piping systems, providing flexibility and resilience to handle dynamic forces, thermal expansion, vibrations, and misalignments. Their versatile applications, ranging from HVAC systems and power plants to chemical plants and pipelines, underscore their importance in maintaining the integrity and efficiency of industrial infrastructure. With flexibility, durability, customisation, ease of installation, and cost-effectiveness, rubber expansion bellows are a reliable solution for ensuring the stability and longevity of piping systems.