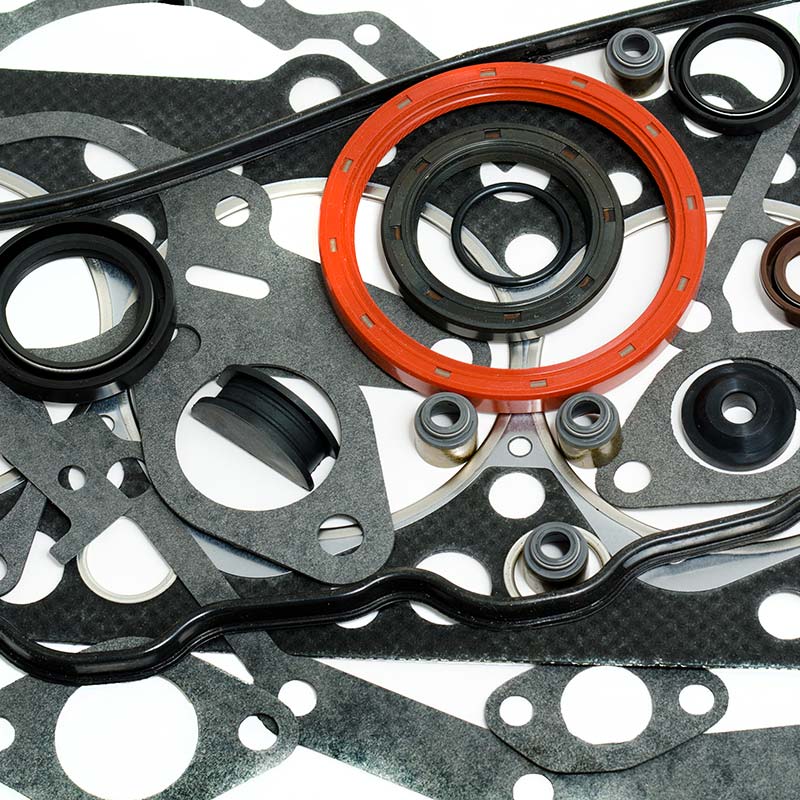

At Flexible Connections Ltd, our commitment to quality, precision, and customer satisfaction sets us apart as a leading UK gasket manufacturer. Rubber gaskets are critical in various industries by providing essential sealing solutions. This detailed overview will explore the intricacies of rubber gaskets, the custom solutions we offer, the materials we use, and the applications of our gaskets across different sectors.

Understanding Rubber Gaskets

Definition and Functionality

Rubber gaskets are mechanical seals that fill the space between two or more mating surfaces, preventing leaks from or into the joined objects while under compression. They are crucial in maintaining the integrity of the connection, especially in systems involving fluids or gases. The primary functions of rubber gaskets include sealing out moisture, preventing leaks, and providing insulation.

Types of Rubber Gaskets

Rubber gaskets come in various forms for different applications:

- Flat Gaskets: Used in flanged connections where the gasket sits between two flat surfaces.

- Ring Gaskets: Common in pipework applications, these gaskets are shaped like rings and fit between cylindrical surfaces.

- Custom Gaskets: These gaskets can be made in any shape or size to meet unique requirements.

Unmatched Durability and Resilience

Our rubber gaskets are crafted from high-quality materials, ensuring unmatched durability and resilience in demanding applications. Whether sealing out moisture, preventing leaks, or providing insulation, our gaskets deliver reliable performance in even the harshest conditions. Their resilience ensures long-lasting performance, reducing the need for frequent replacements and maintenance.

Material Selection

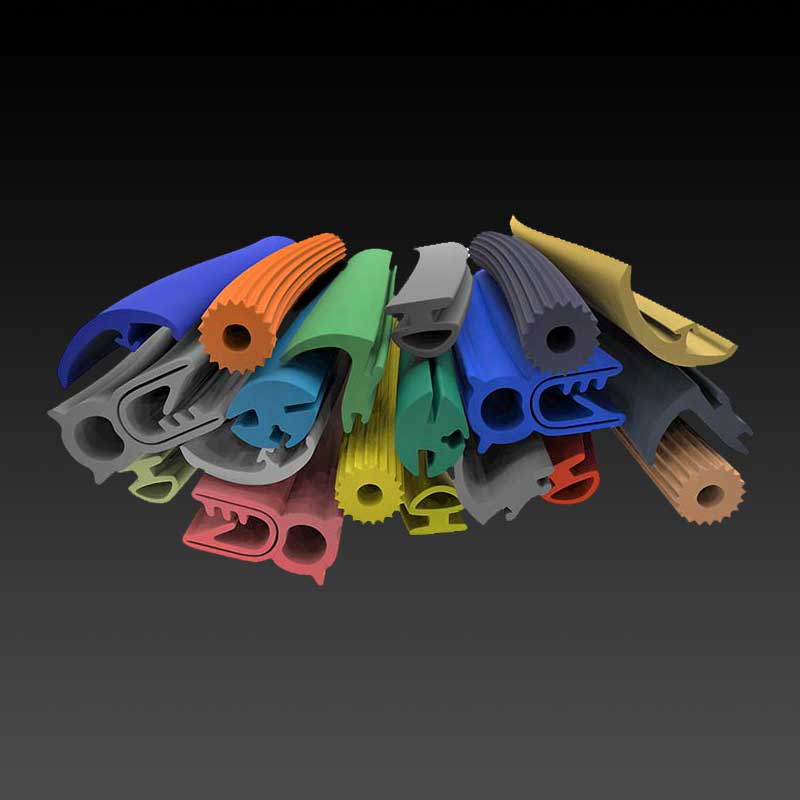

The choice of material is crucial in determining the durability and effectiveness of a gasket. At Flexible Connections Ltd., we offer a range of rubber materials to cater to different applications:

- EPDM (Ethylene Propylene Diene Monomer) is ideal for outdoor applications because it is known for its excellent resistance to heat, ozone, and weathering.

- Silicone: Offers exceptional high and low-temperature resistance, making it suitable for applications involving extreme temperatures.

- Neoprene: Provides good chemical stability and flexibility and is commonly used in refrigeration and automotive industries.

- Nitrile (NBR): Excellent resistance to oils and fuels, making it perfect for automotive and aerospace applications.

Custom Rubber Gaskets Solutions Tailored to Your Needs

Recognising that each project has unique requirements, we specialise in custom rubber gasket solutions. Our experience helps us to understand specific dimensions, tolerances, and material preferences, delivering gaskets that precisely match your application needs. Custom gaskets ensure a perfect fit and optimal performance, addressing any unique challenges presented by specific applications.

Customisation Process

- Requirement Analysis: Understanding the specific needs and applications of the client.

- Material Selection: Choosing the appropriate rubber material based on application requirements.

- Design: Creating detailed designs and specifications for the custom gasket.

- Prototyping: Developing prototypes for testing and validation.

- Production: Manufacturing the final product using advanced machinery and techniques.

- Quality Assurance: Conducting thorough inspections to ensure the gasket meets all specifications and standards.

Benefits of Custom Gaskets

- Perfect Fit: Custom gaskets fit perfectly, eliminating the risk of leaks and enhancing performance.

- Optimised Performance: Tailored to the application’s specific needs, ensuring the best possible sealing solution.

- Versatility: Can be designed for a wide range of applications and industries.

Extensive Range of Materials

At Flexible Connections Ltd., we offer an extensive range of rubber materials, each selected for its exceptional properties. Our range includes:

- EPDM: Ideal for outdoor applications due to its resistance to weathering and ozone.

- Silicone: Perfect for applications involving extreme temperatures.

- Neoprene: Suitable for applications requiring good chemical stability.

- Nitrile (NBR): Excellent for applications involving oils and fuels.

Non-Rubber Materials

In addition to rubber, we also stock non-asbestos CAF (Compressed Asbestos Fibre) material and PTFE (Polytetrafluoroethylene):

- Non-Asbestos CAF: Provides excellent sealing capabilities without the health risks associated with asbestos.

- PTFE: Known for its high chemical resistance and low friction, it is ideal for applications involving aggressive chemicals and high temperatures.

Applications Across Industries

Our rubber gaskets find applications across various industries, including automotive, manufacturing, aerospace, and more. Whether you need gaskets for machinery, HVAC systems, or electrical enclosures, we have the expertise to provide the ideal solution for your project. Some typical applications include:

- Automotive: Sealing engine components, fuel systems, and transmission systems.

- Manufacturing: Used in machinery, equipment, and industrial systems to prevent leaks and ensure smooth operation.

- Aerospace: Essential for sealing fuel, hydraulic, and environmental control systems.

- HVAC: Used in heating, ventilation, and air conditioning systems to ensure airtight seals and prevent leaks.

Quality Assurance at Every Step

Quality is at the core of our UK manufacturing process. We adhere to stringent quality control measures, ensuring that each rubber gasket leaving our facility meets or exceeds industry standards. This commitment to excellence guarantees that our products consistently perform at the highest level.

Quality Control Measures

- Material Testing: Ensuring raw materials meet specified standards before use.

- In-Process Inspections: Regular checks during manufacturing to detect and rectify defects.

- Final Inspection: Thoroughly examine the finished product to ensure it meets all specifications.

- Documentation: Keeping detailed records of all inspections and tests for traceability.

Certifications and Standards

Our gaskets comply with relevant industry standards and certifications, ensuring they meet the highest quality and performance criteria.

Manufacturing Process at Flexible Connections Ltd.

Step-by-Step Manufacturing Process

- Material Selection: Choosing the appropriate material based on the application requirements.

- Cutting: Using advanced cutting techniques to shape the gaskets accurately.

- Forming: Shaping the gaskets into the required form using moulding or other techniques.

- Finishing: Trimming and finishing the gaskets to ensure smooth edges and precise dimensions.

- Inspection: Conducting thorough inspections to ensure the gaskets meet all specifications.

- Packaging: Properly packaging the gaskets to prevent damage during transportation.

Advanced Machinery and Techniques

We manufacture our gaskets with state-of-the-art machinery and techniques, ensuring precision and efficiency. Our equipment includes advanced cutting machines, moulding presses, and inspection tools, enabling us to produce high-quality gaskets consistently.

Large Stock and Quick Turnaround

We maintain a large stock of rubber, non-asbestos CAF material, and PTFE, allowing us to quickly fulfil orders and meet tight deadlines. Our efficient manufacturing process and extensive inventory enable us to provide quick turnaround times without compromising quality.

Conclusion

Rubber gaskets are essential components in various industries, providing reliable sealing solutions that ensure the integrity and efficiency of systems. At Flexible Connections Ltd., we specialise in manufacturing high-quality rubber gaskets tailored to meet the unique requirements of each application. Our commitment to quality, precision, and customer satisfaction sets us apart as a leading UK gasket manufacturer.

With an extensive range of materials, custom solutions, and stringent quality control measures, we ensure that our gaskets deliver unmatched durability and resilience in demanding applications. Whether you need standard gaskets or custom-designed solutions, Flexible Connections Ltd. is your trusted partner for all your gasket needs.

Explore our comprehensive range of rubber gaskets and discover how our bespoke solutions can enhance the performance and efficiency of your operations. Contact us today to discuss your requirements, and let Flexible Connections Ltd. provide you with the perfect gasket solution tailored to your needs.