Applications of Stainless Steel and PTFE Hoses

Both stainless steel and PTFE hoses are used in a variety of industries due to their unique properties and benefits:

- Automotive Industry: Stainless steel braided hoses in automotive fuel, oil, and coolant transfer applications. Their durability and resistance to high temperatures and pressures make them ideal for engine compartments and other demanding environments.

- Chemical Processing: PTFE hoses in chemical plants due to their excellent chemical resistance. They can safely transport aggressive chemicals without degrading, ensuring reliable operation and safety.

- Food and Beverage Industry: Both stainless steel and PTFE hoses in food and beverage production for the hygienic transfer of liquids and gases. Their non-stick and easy-to-clean surfaces help maintain strict hygiene standards.

- Pharmaceutical Industry: PTFE hoses are particularly valuable in the pharmaceutical industry, where contamination must be avoided at all costs. Their non-reactive and hygienic properties make them suitable for transporting sensitive substances.

- HVAC Systems: Stainless steel hoses are used in HVAC systems to absorb vibrations and accommodate thermal expansion. Their flexibility and durability help maintain the system’s integrity, ensuring efficient operation.

-

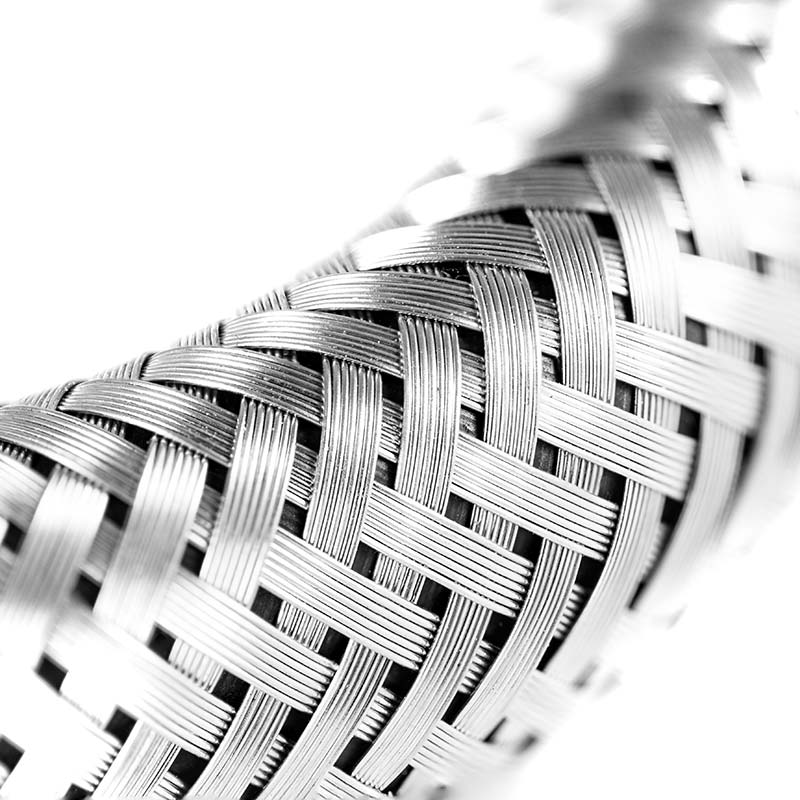

Convoluted Stainless Steel Braided Hoses

Convoluted stainless steel braided hoses are versatile and essential for various industrial applications. They provide a cost-effective and reliable solution to absorb the effects of vibration and misalignment of pipework and machinery, particularly in environments with high pressures. The robust physical strength of stainless steel braided hoses allows them to operate efficiently under high temperatures and pressures, making them a preferred choice in many industries.

Construction and Design

Each stainless steel convoluted hose consists of an inner liner made from a thin-wall stainless steel tube, which is convoluted to provide flexibility. This inner liner design withstands high operating temperatures and pressures while maintaining flexibility. The hose is covered with up to three plies of stainless steel interwoven wire over the braid to ensure pressure containment. This overbraid serves multiple purposes: it acts as a pressure containment mechanism, prevents elongation under pressure, and provides mechanical protection to the hose.

The inner liner’s convoluted design allows the hose to flex and bend without collapsing, making it ideal for applications where movement and vibration are prevalent. The stainless steel braided hose is also fire resistant, adding an extra layer of safety in environments where fire hazards are a concern.

Benefits of Stainless Steel Braided Hoses

- Durability and Longevity: Stainless steel hoses are incredibly durable, offering a long service life even in harsh conditions. The stainless steel construction resists corrosion, abrasion, and wear, ensuring the hose remains functional over extended periods.

- High Temperature and Pressure Resistance: These hoses can operate under high temperatures and pressures, making them suitable for various industrial applications, from automotive to chemical processing.

- Flexibility and Vibration Absorption: The convoluted design provides excellent flexibility, allowing the hose to absorb vibrations and movements. This flexibility helps reduce stress on connected equipment and pipework, thereby preventing damage and extending the lifespan of the entire system.

- Fire Resistance: Stainless steel braided hoses’ fire-resistant properties make them suitable for applications in high-risk environments, such as petrochemical plants and refineries.

- Mechanical Protection: The stainless steel over braid provides additional mechanical protection, safeguarding the hose from external damage and wear.

PTFE Hoses

Pharmaceutical, dairy, and food processing industries use PTFE (Polytetrafluoroethylene) hoses due to their excellent chemical resistance and ability to operate under extreme conditions. PTFE hoses can handle working pressures up to 2000 PSI and temperatures up to 260 degrees Celsius (not simultaneously), making them highly versatile and reliable.

Construction and Design

Depending on the application requirements, PTFE hoses are produced with either a smooth or convoluted inner bore. For applications where a clean, non-stick surface is essential, a smooth bore PTFE Hose is chosen, while a convoluted bore provides additional flexibility. Like stainless steel hoses, PTFE hoses are often reinforced with a stainless steel outer braid to increase the pressure rating and provide extra strength.

A wire helix can be incorporated into the design for vacuum systems applications to prevent collapse under negative pressure. This feature ensures the hose maintains its structural integrity even under vacuum conditions.

Benefits of Flexible PTFE Hoses

- Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, making PTFE hoses ideal for use in industries where exposure to aggressive chemicals is every day. This chemical resistance ensures the hose does not degrade or react with the transported substances.

- High Temperature and Pressure Capabilities: PTFE hoses can handle extreme temperatures and pressures, making them suitable for demanding applications. This high performance ensures reliable operation in challenging environments.

- Non-Stick and Hygienic Properties: PTFE hoses’ smooth, non-stick surface prevents residue buildup, making them easy to clean and maintain. This property is particularly beneficial in the food, dairy, and pharmaceutical industries, where hygiene is critical.

- Flexibility and Durability: PTFE hoses offer excellent flexibility and are ideal for complex routing. Despite their flexibility, they are also highly durable, providing a long service life.

- Versatility: PTFE hoses are suitable for various applications, from fluid and gas transfer to vacuum systems. Their versatility makes them a valuable component in various industrial processes.

Additional Options for Hoses

To further enhance the functionality and performance of both stainless steel and PTFE hoses, several additional options are available:

- Outer Wire Spring Guard: This feature protects against abrasion and mechanical damage. The wire spring guard encases the hose, shielding it from external impacts and extending its service life.

- Internal Stainless Steel Interlock Hose Liner: This option adds durability and flexibility. The interlock liner supports the hose, ensuring it can handle high pressures and demanding applications without compromising its integrity.

- Jacketed Hoses: These are designed for applications where temperature control is crucial. The jacket allows for the circulation of heating or cooling fluids around the hose, maintaining the desired temperature of the transported substance. This feature is handy in industries such as chemical processing and food production.

Conclusion

In summary, stainless steel convoluted hoses and flexible PTFE hoses offer numerous benefits for a wide range of industrial applications. Their ability to withstand high temperatures and pressures and their chemical resistance and flexibility make them indispensable components in many industries. By choosing the appropriate type of hose and additional options, you can ensure your systems’ reliable and efficient operation, regardless of their demanding conditions. Whether you need a stainless steel hose for high-pressure applications or a PTFE hose for chemical resistance, these hoses provide the durability and performance required to meet your specific needs.